Let’s talk obsessive-level loyalty. As far as audio goes, there are perhaps… ten brands, at most, that make audio enthusiasts go weak at the knees. I’m talking fervent admiration and unwavering devotion. Near the very top of that select list sits Accuphase Laboratory. Yes, the quintessentially Japanese success story, widely revered for its uncompromising quality, bulletproof reliability, and intelligent engineering. Then there’s that trademark gold finish and unmistakably elegant industrial design. Yes, I too have admired Accuphase over the years, so what a privilege it was when I was asked to visit the company’s headquarters in Yokohama. And now? I get it. Come join me.

FirstPhase

We arrive at Accuphase HQ, a substantial building from where the company has housed the company’s operations since 1973. I feel a tranquil vibe here, in this setting that contrasts modern Japanese homes set on winding paved streets with lush greenery edging a serenely flowing creek.

Accuphase spawned from a splintering of Trio-Kenwood Corporation to Kensonic Corporation, under the stewardship of founding brothers Nakaichi and Jiro Kasuga. In 1972, the company launched ‘Accuphase’ as a product brand name only (known as ‘Accuphase by Kensonic’). Then, in 1973 there was a move to the current Yokohama location where the first Accuphase-branded products were launched: the C-200 preamplifier, P-300 stereo power amplifier, and the T-100, an AM/FM tuner. In fact, it wasn’t until 1982 that the company changed its name to Accuphase Laboratory as we know it today.

We enter a large meeting room and are greeted by Senior Managing Director Engineering Takaya Inokuma-san and Kohei Nishigawa-san, Manager International Marketing Division. Soon after, we’re joined by company President Masaomi “Mark” Suzuki and none other than founder-Corporate Advisor Shigemasa “Jim” Saito-san.

Senior Managing Director Engineering Takaya Inokuma-san and Kohei Nishigawa-san, Manager International Marketing Division.

Senior Managing Director Engineering Takaya Inokuma-san and Kohei Nishigawa-san, Manager International Marketing Division.

President Masaomi “Mark” Suzuki and founder-Corporate Advisor Shigemasa “Jim” Saito-san.

President Masaomi “Mark” Suzuki and founder-Corporate Advisor Shigemasa “Jim” Saito-san.

The room is lined with classic Accuphase models spanning various generations. Within the kaleidoscope of Accuphase-ness, one particular component sticks out with super-conspicuous presence. Front and centre, among the varied tones of signature gold, is a single component sticks out in… Henry Ford black! Blasphemy. It turns out it’s a unit which was part of a special request run. Once only. Subtle golden tones are in the Accuphase DNA, after all.

We start by receiving a brief overview of Accuphase’s history and product development by Inokuma and Ishigawa. They also outline ongoing company growth was the catalyst for a relatively recent extension of the factory into an adjoining building.

In that annexe, Accuphase houses its vast warehouse which is brimming with boxed and ready-to-ship Accuphase products. In my experience visiting dozens of audio manufacturing facilities, this is likely the largest stockpile of inventory I’ve seen.

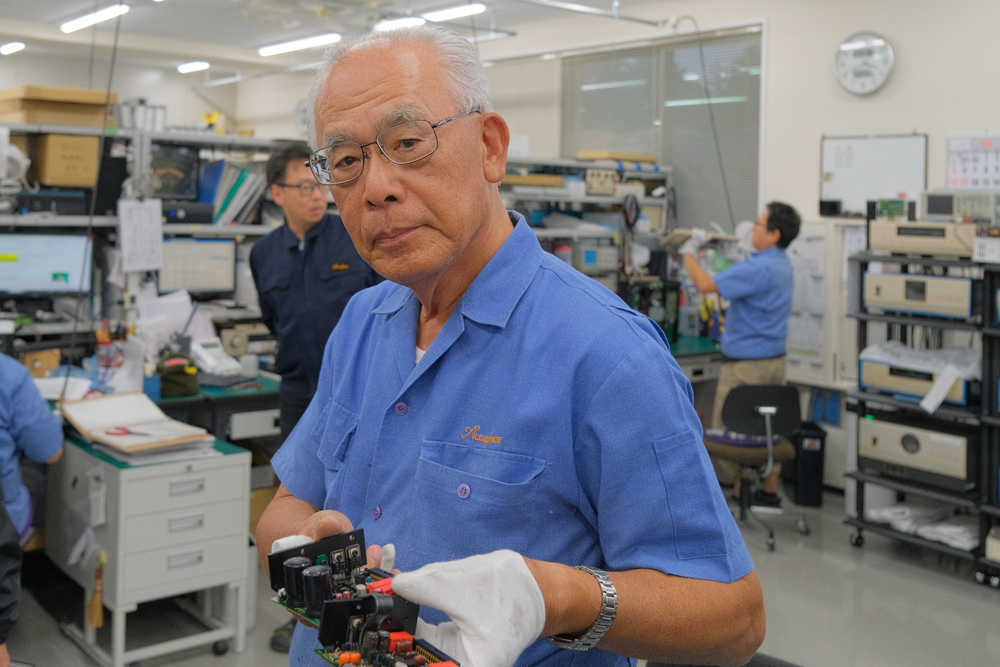

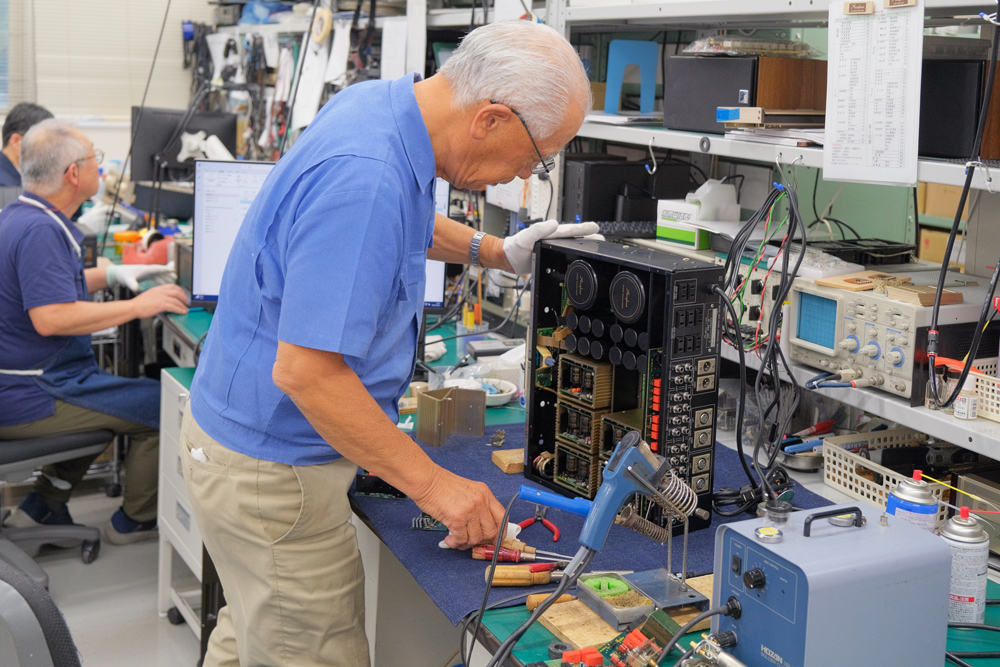

There too is a department not often seen, especially in the western audio industry. Accuphase has operated a full servicing department since its inception, primarily catering to the local Japanese market. It’s fully equipped with modern testing equipment and staffed by a team of service personnel under the mentorship of Shibuya-san, a “legendary” technician who has been with the company for over 50 years. Also housed in the new wing is one of two dedicated listening and testing rooms along with smaller ancillary workspaces.

Shibuya-san has been with Accuphase for over 50 years.

Shibuya-san has been with Accuphase for over 50 years.

A brief Q&A follows. Inokuma explains that, as has always been the case, but is now given even more focus, is the combined efforts of Accuphase engineers to reduce circuit noise and distortion to the lowest possible levels. Subjectively, the engineers aim for a spatially generous and detailed yet engaging sound. Given their revered status, I ask whether comparisons are made with previous generations of products, even very early ones. I’m told, yes, absolutely. The comparisons inform the design team and can, in some way, even influence product development. After some more exchanges, we’re signalled it’s now factory tour time.

Producing Excellence

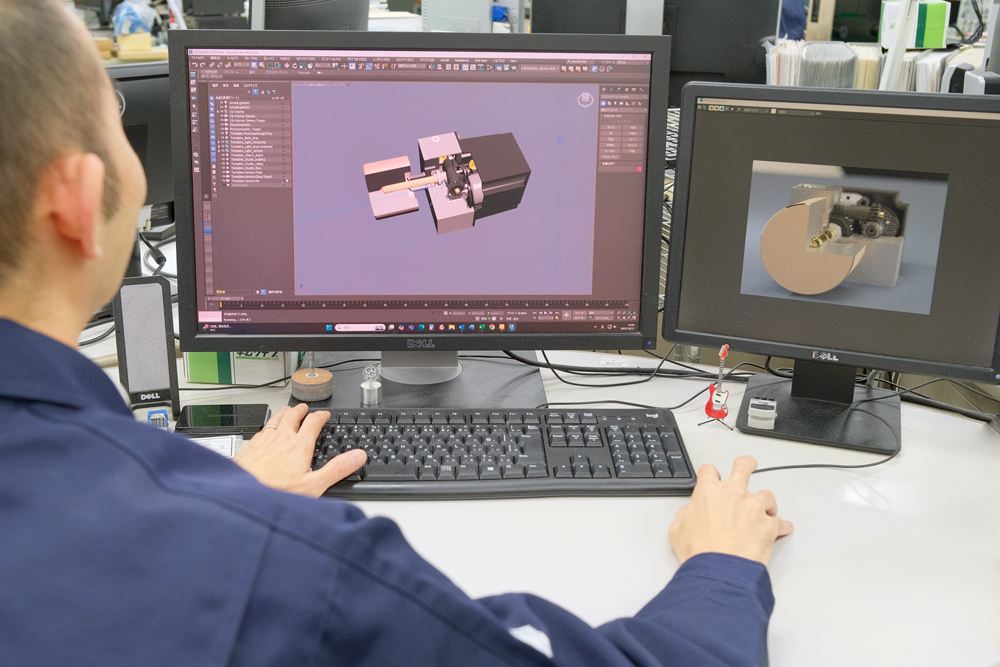

With our two guides in Inokuma and Nishigawa, we first enter the Research and Development and Mechanical Design department. In this open space a team of two or three designers work on set projects, with a varied number of projects running concurrently. Each project may have a two to three year gestation period.

Designer fine-tuning volume control mechanism.

Designer fine-tuning volume control mechanism.

Design work applies across all aspects of a product, including proprietary digital technologies, FPGA and operational/logic systems such as ‘Accuphase Analog, Vari-gain Amplifier (AAVA) gain topology, ‘Multiple Double Speed DSD’ (MDSD) SACD-dedicated technology, and more. At the last stages of a product’s development, a number of prototypes are produced for parts of a product that have a certain level of complexity. Subsequently, the entire product is prototyped. Testing is exhaustive and the R&D technicians have a subjective input into the sound of the component being designed beyond the computer simulations.

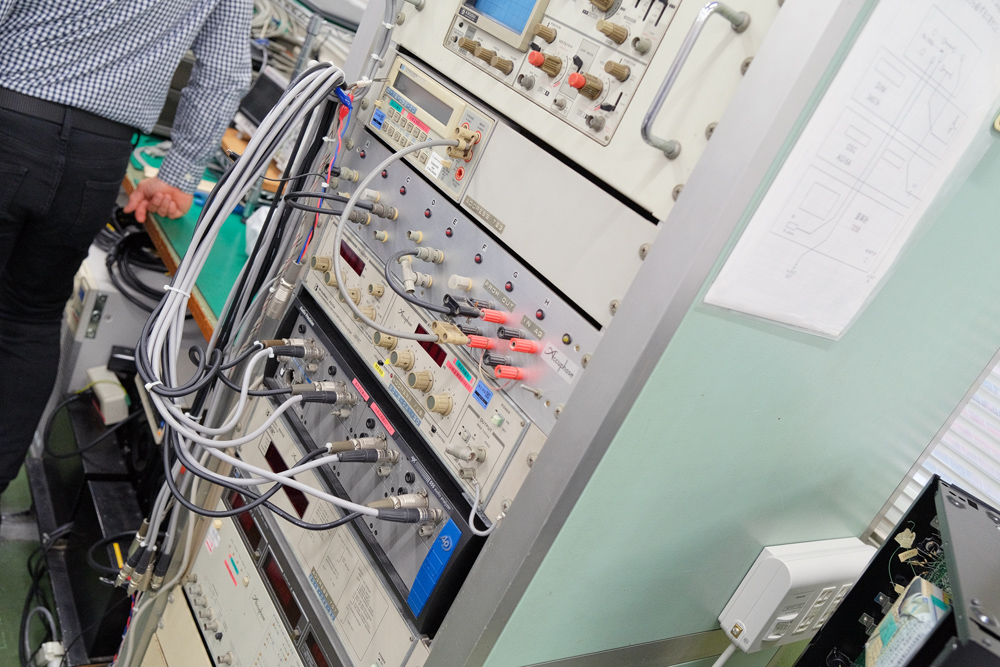

Accuphase Programmable Low-Distortion Oscillator (fourth component down), a one-off analogue component purpose-designed by Accuphase engineers is racked with a bank of testing equipment. Among the racked testing gear are several other bespoke Accuphase components.

Accuphase Programmable Low-Distortion Oscillator (fourth component down), a one-off analogue component purpose-designed by Accuphase engineers is racked with a bank of testing equipment. Among the racked testing gear are several other bespoke Accuphase components.

Testing equipment is everywhere, a testament of Accuphase’s engineering-based philosophy. Brands used for measurements, design, testing, etc. are a who’s who of the best available, including testing equipment from Audio Precision, Hewlett-Packard, Accuphase’s own bespoke units and others.

Past the R&D department we enter the first listening room. It’s an environment thoughtfully designed to mirror the dimensions of a typical living space, or lounge area, at least by European, American and Australian standards. Here, an assortment of the latest Accuphase electronics is paired to Bowers & Wilkins 801 D4 loudspeakers. The room passes the clap test through its use of acoustic panelling and a variety of diffusors delivering a neutral sound with excellent dynamics and generously proportioned spatial qualities.

From there we step into the factory proper, where I see rows of semi-assembled components await the next stage in the build process. There’s a strong sense of precision and efficiency to the process which has been mindfully planned right from early to full assembly, to testing, burning-in, quality control, packaging, and warehousing in readiness for shipping. I’m told that a production batch of 100 components, from go to whoa, takes about a week.

Once mostly assembled (minus the front panels and other trims), a series of tests and measurements are taken. Each station features banks of equipment that are used for the testing, measurements, and calibration stages.

Then, the final stages of assembly and general QC processes begin. Once a product reaches the mandated specifications, it moves to the next assembly line process where the front panels are mounted and inspected for imperfections. The smallest mark means a panel is rejected and is then recycled.

The product is put through a series of further strenuous tests. Even the displays are measured against the reference for brightness matching. Once all done, the burn-in sessions begin and will go from between 24 hours to 48 hours.

The next step would make the average component tremble with anxiety and bead at the brow. Rough and ready couriers… bring it on! The product proceeds to a vibration simulation area where a shaking platform is set to produce varying degrees of shock in order to mimic differing stress conditions. Beyond that arduous test, and even unconventionally, the operating technician delivers forceful, deliberate strikes to the top and side panels of each component to further test the integrity of the circuits and the overall mechanical stability. It’s a final stress check that can reveal the capacity for withstanding real world handling.

Once the shock and awe brutality is over, more tests are done to check the component’s circuit, voltage leakage, and mechanical integrity. Of course, all functions and features are tested again. Within reason, Accuphase takes no chances.

Above, Inokuma shows QC sheets which are kept for perpetuity. These records go back to Accuphase’s very early days. It’s at this stage that a product moves on to the packaging area where it meets its own Owner’s Manual, accompanying accessories, remote control, cables, etc.

Accuphase’s massive warehouse and finished product storage space is super-impressive. Shown here, and earlier in this feature, are just two examples from a battalion of several bays each holding similarly voluminous quantities. Yes, the rows of well-organised inventory illustrates the scale of Accuphase’s operation.

Introduced above, team leader of Accuphase’s service division Shibuya-san is shown at his workstation. Every Accuphase product can be serviced and rebuild to its original design. If an externally supplied part is no longer available, Shibuya and his team will endeavour to make it. That’s the truest meaning of service. Plus, I’m told reassured by Shibuya that Accuphase takes user feedback and opinion very seriously, whether from its distributors, partners and even directly, at times resulting in minor modifications and alterations of mutual benefit.

The Accuphase ethos values education, teamwork, and the sense of a team striving towards a common goal. Shown above is a sizable dual purpose lunchroom and education facility.

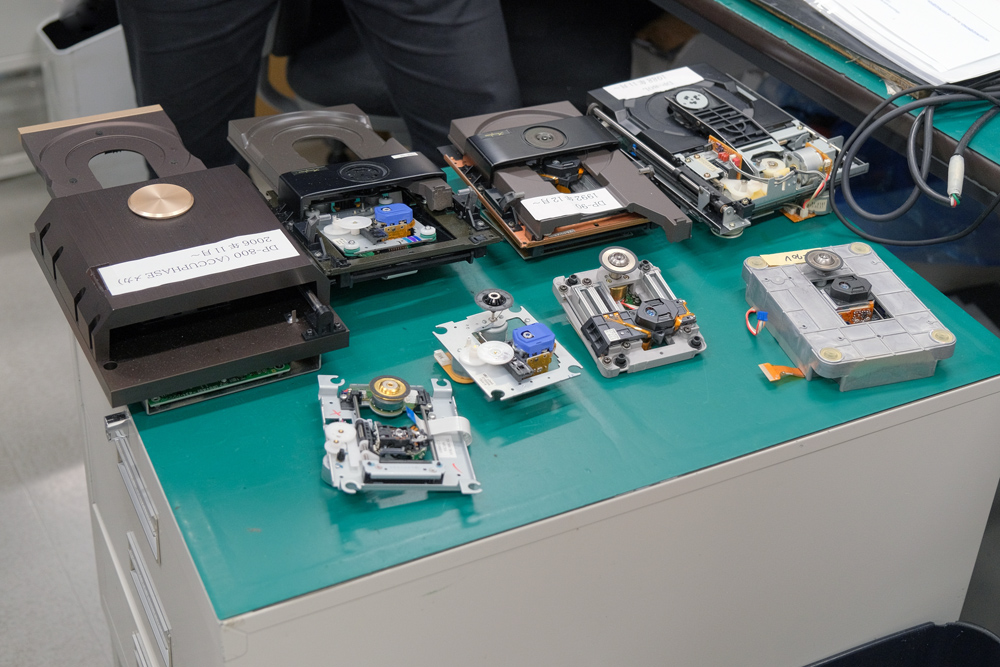

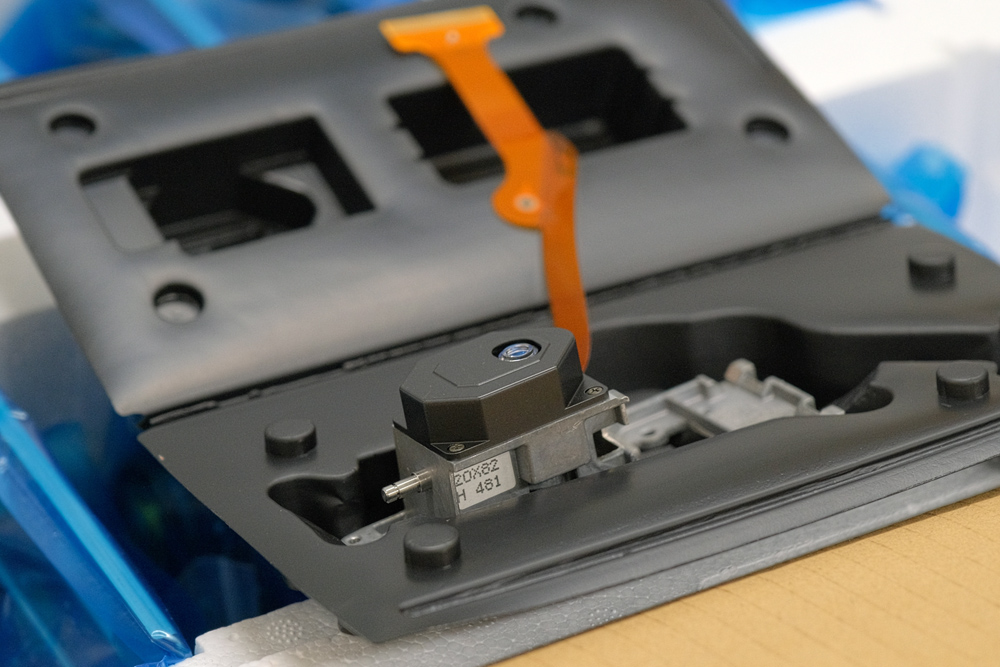

Naturally, the company keeps spare parts for all is products, past and present. Especially important at these times, Accuphase continues to design, stock, repair and restore its CD/SACD player mechanisms using refreshed parts and components. In fact, its spare parts department requires a small, dedicated warehouse, such is the scale of its inventory. Also shown above (the second image) are two roadcased samples of Accuphase’s formidably over-engineered SACD transport mechanism. They are truly of tank-like build quality, weighing in at nearly 11 kg each and constructed from solid aluminium and aluminium alloy. The image below the SACD mechanisms shows a spare part of significance: a bespoke laser assembly for Accuphase’s first ever CD player, the highly acclaimed DP-70.

We end the tour in Accuphase’s second and main listening room. I’m told that teams of assessors that include engineers, R&D personnel, and management spend time here evaluating prototypes and new products. A bank of Accuphase’s very best electronics provides the signal flow to a pair of Bowers & Wilkins 801 D4 Signature speakers while a pair of Fyne Audio F1-12S offers and alternate sonic flavour. It’s quite a large and beautifully appointed room that has been expertly treated with acoustic panelling. The mix of sound absorption and diffusion has resulted in an RT60 of 0.25 seconds and a very quiet noise floor of 20dB. It’s an excellent sounding space.

We’re invited to a short listening session and to conduct an A/B test between the current generation C-3900S preamplifier and the previous generation C-3900. While both components sounded excellent, I found the C-3900S was somewhat more refined, spatially layered and neutral sounding. Similar findings were revealed when A/B-ing between the stunning new DP-570S and its preceding DP-570 SACD players. Analogue playback provided by a C-570 phono stage receiving signal from a Yamaha GT-5000 turntable fitted with an Accuphase AC-6 Moving Coil cartridge. Amplification is via the massive A-300 Class-A monoblock power amplifiers.

Conclusion

Left to right: Tatsuki Tozuka, Takaya Inokuma, Masaomi "Mark" Suzuki, Shigemasa "Jim" Saito (founder), Kohei Nishigawa

Left to right: Tatsuki Tozuka, Takaya Inokuma, Masaomi "Mark" Suzuki, Shigemasa "Jim" Saito (founder), Kohei Nishigawa

Personally, Accuphase has long carried an air of mystique… I want to say almost reverence. Yet, for whatever reasons, it has remained at arm’s length. Visiting the factory has changed all that. Gaining insight into the facility’s working processes, witnessing the meticulous craftsmanship firsthand, meeting the people behind the products, and grasping the sheer scale of the enterprise left a lasting impression.

The mystique may remain… after all, the company’s products, especially the upper-tier models, exude alluring desirability. Yet now it’s become something… tangible. All these aspects of fabrication, the commitment to intelligent engineering, the obsessive attention to detail, the uncompromising level of circuit and hardware integrity, the respect of tradition while progressing innovation, all are elements of the quiet ‘golden’ brilliance that defines Accuphase.

… Edgar Kramer

This email address is being protected from spambots. You need JavaScript enabled to view it.

Accuphase Laboratory

2-14-10 Shin-Ishikawa, Aoba-ku

Yokohama City, Kanagawa Prefecture, 225-8508

Japan

+81 (045) 901 2771

www.accuphase.com

Australian Distributor: Advance Audio Australia

+61 2 9561 0799

www.advanceaudio.com.au